Our Machining Facility

LMW Make – Smart Turn Plus (CNC Turninng)

8″ Chuck Size

LMW Make – LL20T L5 (CNC Turninng)

10″ Chuck Size

LMW Make – LL25T L7 (CNC Turninng)

12″ Chuck Size

LMW Make – LTV 50 (Vertical Lathe)

24″ Chuck Size / 800 x 800mm Swing over

LMW Make – JV55 (CNC Milling)

Table Size X-800 x Y-475 x Z-500

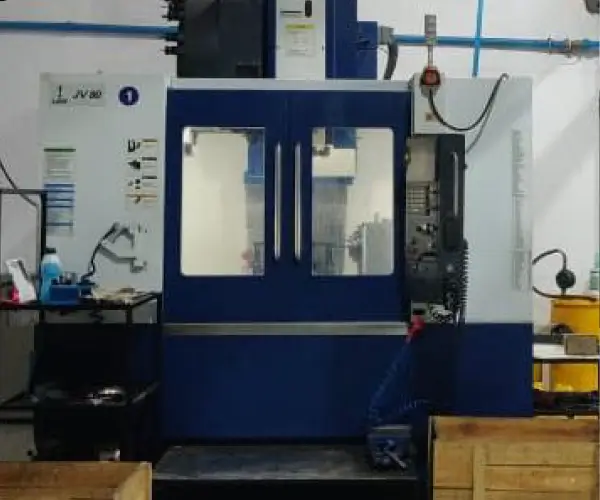

LMW Make – JV 80 (Vertical Milling Centre)

Table Size X-1000 x Z – 900 x Y-600

LMW Make – JV100 (CNC Milling)

Table Size X-1250 x Y-650 x Z–700

Our QA/QC Facility

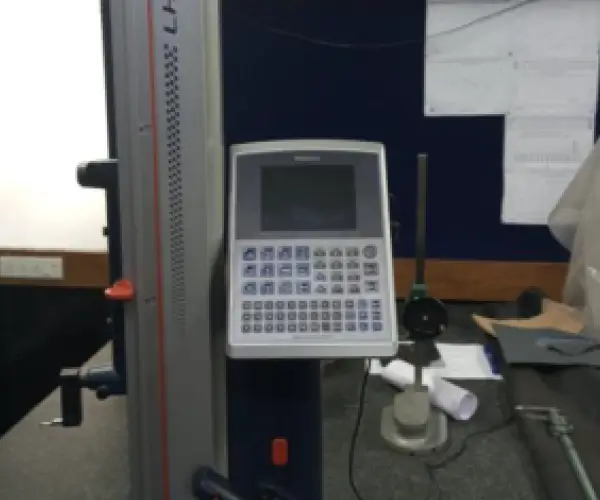

CMM

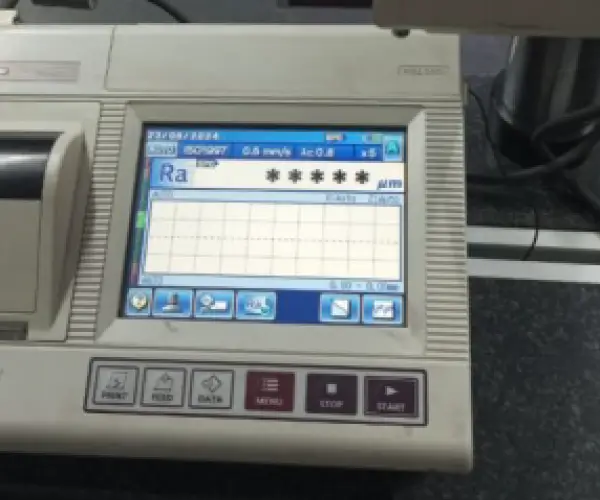

Mitutoyo Cmm Crysta-apex V With Mitutoyo Height Gauge Mitutoyo Roughness Tester Universal Renishaw Probe.

Size : X-700mm x Y-1000mm x Z-600mm

Mitutoyo Height Gauge

Mitutoyo Roughness Tester

Future Plan For Machining Facility

VTL Series

VTL2000ATC Series

Specification

- 1. Max. swing diameter Ø2500 mm

- 2. Max. turning diameter Ø2300 mm

- 3. Max. turning height 1600 mm

- 4. Max. work-piece weight 10000 KG

- 5. Spindle speed 200 rpm

LMW MAKE – JH500

(HMC)

Specification

- Table Size : 800 x 800 x 800